EcoBlue’s Managing Director, Mr. Pranay Jain took part in a consultation workshop on Plastics Circularity: Opportunities and Barriers for the Private Sector organized by The Pollution Control Department of Thailand and the World Bank. The findings from the workshop would be used to inform a market study on plastics circularity, opportunities and barriers in Thailand, a study commissioned by the World Bank. GA Circular has been engaged to conduct the market study and had facilitated the consultation workshop in Bangkok on 28th February, 2020.

At this workshop, Pranay made a presentation on Recycling – Challenges and Solutions. He spoke about how only about 12% of the 300 million tons of plastics being used gets recycled at a global level. Thailand has a plastic production about 10 million tons with a recycling rate of about 5%.

Recycling has been identified as the backbone of a sustainable economy. However, currently the demand for recycled plastics is limited to bottles and apparels which do not improve the overall recycling rates.

The recycling rates have been declining in the recent 6 months due to the decline in oil prices and virgin resin prices making recycling not an economically lucrative activity. Apart from economic challenges, recycling is facing many challenges from other fronts like government policies that are deterrent for recycling industry and poorly designed packaging which reduces the output of recycling. Use of PVC labels, printing on bottles and cups, PP cups with PET Caps, full body labels, pumps etc. are some examples of poorly designed packaging which reduces the recyclability of the same. Design for recyclability has to be a key focus area for packaging industry!

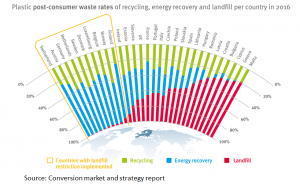

A drop in recycling rate means more and more plastic waste is being land filled, littered or reaching our oceans. Only voluntary measures cannot bring about the desired change. A policy framework needs to be put in place. For example, the 10 million tons of pledge for recycled content by EU is prompting companies to make commitments that can be measured. Studies have shown that Extended Producer Responsibility & Landfill restrictions are the most effective measures for improving the recycling rates.

We have to work towards creating an environment where recycling can thrive. It would need:

- Design for recycling guidelines

- Creating a market for recycled polymers so that recycled plastics can survive even when the virgin prices are low

- Permit use of recycled materials in food contact applications

- Conduct risk assessment studies for single use plastics to categorize and prioritize actions to be taken

- Redefine BOI policies to include washing etc as a promoted activity.